What Is Construction Fleet Management?

Managing a construction company comes with many challenges. Some of the most common issues include minimal vehicle visibility, low driver satisfaction, poor communication, delayed cash flow, and unrealistic or inaccurate forecasting.

When these issues persist or are left unresolved, they threaten the success of a viable company. In order to see continued growth, construction companies must implement reliable and efficient construction fleet management.

Tread’s cloud-based construction fleet management software makes the business of moving construction materials easier, faster and more profitable. Request a demo today.

What is construction fleet management?

Construction fleet management is the process of planning, directing, and overseeing construction fleet assets to improve and optimize business operations. This includes fleet vehicles, operators, dispatchers, and other stakeholders.

Construction fleet management gives companies visibility into and control over their fleet operations, allowing them to understand and improve this key business function.

What is involved in construction fleet management?

Construction fleet management involves planning, directing, overseeing, and reporting on construction fleet vehicle and operator activities through various tools and applications.

In short, construction fleet management involves:

- Route planning

- Fleet vehicle monitoring

- Operator direction and supervision

- Data collection and reporting

These duties are performed offline and online through various forms of data collection and record-keeping. How these duties are performed varies from company to company; however, due to new regulations, more construction companies are moving to a strictly online, digital, and paperless approach.

What are the benefits of construction fleet management?

Construction fleet management allows companies to efficiently manage their fleet and operators; increase productivity; and improve invoicing, budgeting, forecasting, and compliance. These benefits are all achieved through the collection and analysis of raw fleet data.

Here are four major benefits of construction fleet management programs:

1. Optimize Fleet Vehicle & Operator Performance

Effective construction fleet management involves collecting, storing, and analyzing vehicle and operator data. With complete, reliable data — such as purchase history, mileage, accident history, mechanical diagnostics, maintenance and repair records, previous drivers, routes — fleet managers can have a deep understanding of fleet vehicle and operator history and performance.

This historical data enables construction fleet managers to make more informed business decisions, which serve to increase productivity, advance growth, and refine daily operations.

Vehicle maintenance and repair is a major cost for construction fleets. Ensuring construction vehicles avoid costly, unnecessary, repairs, requires adherence to a proper maintenance schedule. If there is an accurate and reliable record of previous maintenance and recommendations, construction companies can ensure the proper steps are taken to maintain their fleet. And as we all know, proper maintenance increases the longevity and lifespan of vehicles. Meaning less unnecessary costs and safety risks.

Regular maintenance also helps keep fleet vehicles running at maximum efficiency. Maintaining the proper tire pressure allows fleet vehicles to perform at their peak capability, traveling at maximum efficiency, and in the best possible time while using the least amount of fuel.

More than the vehicles themselves, regular fleet maintenance means a higher level of safety for operators, and a higher level of safety means more job satisfaction and lower turnover rates.

Read More: How to set up a truck driver safety incentive program

.jpg?width=760&height=427&name=Tomlinson%20Group%20-%20Oct%2024%202022%20(6).jpg)

2. Increase Productivity & Workflow

When an effective construction fleet management system is put into place, it minimizes delays, errors, and issues that disrupt workflow. Construction fleet management allows businesses to have an overarching, all-encompassing understanding of assets, project requirements, and more. For example, fleet managers are able to use historical project information to plan more efficient routes that require less mileage and fuel. Understanding the most efficient routes is better for a company’s finances and the environment.

Fleet managers are also able to use this data to help them assign the right people for the job. Having the right people on the right routes means tasks get done better and on time.

When valuable project information is organized, stored correctly, and easily available through construction fleet management, it makes it easier for those involved in a project to access the information they need to complete the job. With better data, jobs are assigned on time, to the right people, and to be done in a timely manner. Construction fleet management allows for maximum organization and keeps everyone accountable and on top of the tasks that are needed to keep projects moving forward and on time.

When a company is being managed efficiently and effectively, it speeds up productivity and workflow. When a project is accurately planned and delegated, and when everyone involved has exactly what they need to do their job without delay or error, the output is at maximum efficiency.

3. Improve Invoicing

Construction fleet management ensures accurate, organized, and trusted handling of invoicing. Ticketing, billing, signatures, payments, route logging, and time tracking have traditionally been handled manually, then uploaded to a digital platform. However, new regulations encourage all invoicing and transactions to be done digitally.

Improved invoicing occurs when construction companies adopt a paperless approach. This includes e-ticketing and digital record keeping which ultimately improves data safety and security.

When tickets are signed, saved, and processed electronically, it makes them easier and faster to access by drivers and sub-contractors. This speeds up payments and increases trust between stakeholders.

Additionally, financial record-keeping on a digital platform is organized and accurate, minimizing payment errors and misses, and allowing construction companies to look back at payment history quickly and easily.

4. Better Budgeting & Forecasting

Construction fleet management minimizes operational expenses through the historical insights collected over time. Metrics collected can offer construction companies valuable insights and understanding of where projects are making money or losing money.

Operational expenses such as fuel, maintenance, and tire wear can all be reduced with construction fleet management. Monitoring and providing insights into vehicle and operator performance can drastically reduce fleet maintenance frequencies. Additionally, data-supported route planning can reduce the wear on tires and decrease replacement cycles.

Data collected through construction fleet management can also be used for better scheduling. Understanding which drivers perform the best and which routes minimize drive time can speed up project flow and maximize operational efficiency. Valuable information captured from existing workflows, allows business owners and managers to optimize trucking routes and material movement.

Order accuracies increase by 15% when using construction management order forms to estimate and bid on projects. And reporting gives businesses maximum visibility so they are better able to forecast and predict expenses and revenue and overall generate more accurate budgeting and projections.

.jpg?width=760&height=570&name=Perrault%20Trucking%20%26%20D3%20-%20July%202022%20(2).jpg)

How to improve construction fleet management?

Fleet management is essential to running a successful construction company. Monitoring and measuring fleet and operator data improves productivity and minimizes expenses. However, this can all be enhanced, made easier, and even more efficient by introducing a cloud-based, automated construction fleet management software.

What is construction fleet management software?

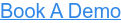

Construction fleet management software, or FMS for short, is cloud-based, automated technology that provides accurate, real-time data on vehicle and operator performance. Action-based reporting helps construction companies further improve the benefits of fleet management.

Data like vehicle location, direction, and performance are all gathered through construction fleet management technology. Even information on driver behavior can be collected. Information like harsh braking, aggressive acceleration, idling, and more.

Switching to a digital fleet management program also makes it easier to work with drivers who speak different languages. Which helps improve communication, workflow, and overall job satisfaction.

Construction fleet management software moves invoicing, payments, route logging, and more from the slow-moving, inaccurate days of manual paperwork to a paperless, digital platform that provides accurate, high-speed solutions. Tickets can be stored and easily accessed by a construction company’s drivers and sub-contractors. Tickets can also be signed, saved, and processed electronically, all from a smartphone or tablet. Going paperless and implementing a cloud-based fleet management system also eliminates errors in route logging and driver tracking. Digital tracking means there is no more estimating or guessing drive-time or driver hours.

Automated reports are generated with useful vehicle, route, and operator data that can be used to decrease company expenses, improve budgets, and enhance forecasting.

Fleet management systems offer construction companies everything they need to know about their vehicles — all on one organized and user-friendly digital platform.

Construction fleet management technology makes the business of moving construction materials easier, faster, and more profitable.

How does construction fleet management technology work?

Construction fleet management technology is a sophisticated system that can be installed in fleet vehicles or drivers’ mobile devices and uses GPS and integrated technologies to send data from fleet vehicles to a central database. Tread’s technology is a smartphone app that eliminates the need for costly hardware installation in fleet vehicles.

Vehicle operators are required to install an application on their smartphones in order to share data with the fleet management system and to communicate with dispatch.

Fleet management systems rely on an integrated network, which exchanges real-time information and data so it can be stored, analyzed, and referred to when planning future projects.

Request a construction fleet management demo

Build on the innate benefits of construction fleet management with our advanced and fully-integrated system. Tread’s efficient construction fleet management software drives 30% time and cost savings for dispatch activities and makes businesses safer and more profitable.

If you’d like to learn more about how Tread can benefit your business, click the button below to request a demo.

Read On

Truck Driver Safety Incentive Program: 5 Key Practices

When you’re in charge of a truck fleet, driver safety should be paramount. As demands on truck...

Unveiling Tread Horizon: The Ultimate Construction Materials Intelligence Platform

Pioneering a Comprehensive Platform for the Construction Materials Industry

13 fleet truck fuel management best practices

Fuel is the second-largest fleet-operating expense year after year. On average, it eats up 60% of a...