6 Benefits of Construction Material Management

Money doesn’t grow on trees, and construction materials don’t appear out of thin air either. Material management is a complex and crucial part of every construction project. While many people associate it primarily with the purchasing and delivery stage, material management actually stretches across a much wider range of activities; from planning and procurement all the way through to waste management and disposal.

A well-executed material management strategy can generate significant cost savings and improve project efficiency. A poorly executed one can lead to major delays, safety concerns, and decreased profitability.

Learn about the role of construction material management and the key part it plays in the success and profitability of construction projects of all sizes.

What is construction material management?

Construction material management is the process of sourcing appropriate materials at a reasonable cost and ensuring their availability — at the right place and time — to meet project requirements and deadlines. It is a vital function for construction projects of every scope.

The quality of your construction material management can make or break a project budget. A poor materials management strategy risks skyrocketing costs through decreased labor productivity, material waste, and missed project milestones and deadlines. However, a dialed-in strategy has some major benefits, which we will discuss in more detail.

Digitize your workflows and control material costs with Tread’s construction fleet management software. Request a free demo now.

What are the types of construction material management?

Construction material management encompasses a wide range of activities throughout the project lifecycle, including:

- Materials planning and purchasing

- Scheduling and transportation

- Receiving and quality control

- Storage and inventory management

- On-site transport

- Waste management

What are the benefits of construction material management?

Given its impact on workflows and profitability, investing in improvements to your materials management system can bring significant positive impacts to your overall construction management efforts. Some of the many benefits of construction material management include:

1. Maximize Worker Productivity

Labor expenses are a common target for cost reduction measures in the construction industry. The most common way to achieve these cost savings is typically to reduce labor hours and wages as much as possible. Worker productivity, however, is often overlooked as a way to keep costs down. Effective material management can play a key role in maximizing productivity.

A construction crew needs to have the right supplies at the right time in order to accomplish their objectives. The more time spent waiting for equipment and material deliveries or tracking them down on the construction site, the less they are able to accomplish and the likelihood of project delays or paying overtime costs increases.

2. Minimize or Eliminate Duplicate Handling of Materials

Another source of reduced labor productivity and its associated costs is material handling, which often accounts for up to 40% of a team’s time on a job site. A good material management system includes proper communication, scheduling, and tracking tools. With these, sites are prepared for materials and they can be deposited and stored in the most ideal location. This level of management ensures workers aren’t wasting time moving materials and equipment when they’re needed.

Ideally, material deliveries should be scheduled so that the appropriate staff are on-hand to receive and inspect them. Project materials should be unloaded into an available storage area or as close as possible to where they’ll be used. This avoids unnecessary duplicate handling, which can save time and also minimizes the risk of damage that can occur during relocation. Ultimately, the less time spent moving materials, the better.

3. Lower the Chance of Theft or Weather Damage

The faster supplies can be used upon delivery to a construction site, the better. This is particularly true when there are minimal (or non-existent) secure, weather-proof storage facilities.

Accurate scheduling — as well as acquiring the correct quantity of construction materials — reduces the time that they sit at a job site unused. This minimizes their exposure to the elements and potential weather damage, as well as avoiding becoming a target for theft.

4. Reduce Material Waste

Effective material management systems not only ensure that materials are in the right place at the right time, but that the right type and quantity are acquired in the first place.

Purchasing the wrong construction materials can lead to a number of problems, from minor delays all the way up to safety hazards. Incorrect materials can even lead to contract penalties if they don’t meet project requirements/code or if they cause missed deadlines.

Similarly, a lack of required materials will result in additional costs and construction delays while searching for or waiting for more to arrive. Ordering additional supplies in smaller quantities typically comes at a higher cost per unit than bulk materials, which further increases the total cost. It could also lead workers to substitute in materials that could be inadequate, again leading to safety concerns or contract penalties from not meeting project requirements.

On the other hand, excess product leads to material waste. This is costly for construction projects, due to spending money on unneeded materials and the associated storage and disposal costs. Material waste can also arise from deterioration in storage, either due to improper storage conditions or being delivered too early and expiring before being used.

Material waste can easily be reduced in the project planning, purchasing and inventory management stages of a good material management system.

5. Improved Budget Accuracy and Forecasting

Material and labor make up a significant portion of construction project costs, even when things are running smoothly. But when problems occur, these costs can explode, due to decreased productivity and project delays.

A comprehensive material management strategy helps to prevent these problems from occurring, which ultimately leads to more accurate budgets and forecasting. Having a more accurate understanding of the existing inventory and future needs will lead to more accurate budget forecasts when changes or updates are required.

6. Greater Adherence to Project Milestones and Deadlines

You’ve already seen the many ways that a poorly implemented material management system can impact your construction activities. At the end of the day, when workers have what they need, where and when they need it, they’ll be able to get their work done on schedule. This will keep the entire project on track, hitting milestones and deadlines, and — most importantly — avoiding financial penalties of not meeting these objects.

The Benefits of Investing in a Material Management Software

An effective material management system involves a lot of moving parts (figuratively and literally) and numerous stakeholders. The reliance on pen and paper methods of organization in the construction industry can often lead to errors and miscommunications, which contributes to many of the problems and delays discussed above. Many construction companies are starting to turn to digital solutions as a way to address these problems.

Transitioning your project team to a paperless material management system can bring many benefits such as:

- Increased order accuracy

- Faster payments and increased trust between subcontractors and vendors thanks to digital invoices

- Improved scheduling of material delivery to minimize delays and maximize backhauling opportunities

- Digital tracking of high-risk materials

- Better organization and access to information through digital storage of all documentation such as order forms, invoices and scale-house tickets

- Improved accuracy in budget forecasting and scheduling from better access to up-to-date data

Want to take advantage of all these benefits and more? Tread is a materials management software built for fleets, brokers, material producers, general contractors and excavation sites across North America. We help you make your businesses more profitable.

Digital Material Management with Tread

By digitizing your material management system, Tread will help control material costs and take your construction project and material management to the next level.

Request a demo today to learn more about Tread’s construction fleet management software and how it can help digitize your workflows and grow your business.

Read On

5 Tips for Construction Material Delivery

Reliable, on-time construction material delivery is key to profitability on any construction...

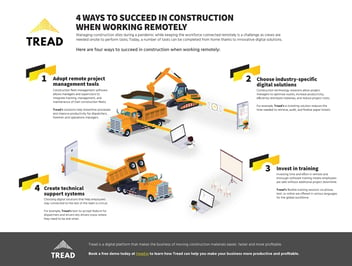

Remote Construction Site Monitoring: 4 Ways to Succeed

From rising material costs to labor shortages, construction faces a number of obstacles to overcome...

How to Grow an Efficient Construction Business

Scaling your construction business from small, to medium, to large requires a lot of work. There...