What Construction Companies Can Learn From Southwest Airlines

Over the holidays, Southwest Airlines had a nightmare unfold. They canceled more than 2,000 flights (71% of its flight schedule) on December 26 for safety reasons and almost 17,000 flights in December in total. And the cherry on top? They’re now being sued by their shareholders.

But what does this have to do with the construction industry? Southwest Airlines operates all over the continent, with hundreds of planes across dozens of locations. How can that relate to a construction company that operates out of one or two central locations, with only a few quarries or sites or projects to manage?

To get that answer, you need to examine WHY the Southwest Airlines debacle happened. Southwest consistently delayed upgrading its software infrastructure. Their antiquated process relied on pilots calling in to report their location if a flight was canceled. When one bad storm hit, Southwest became overwhelmed with calls and quickly lost track of where most of its crew members and pilots were, eventually snowballing into an almost complete shutdown.

A system built on old systems, phone calls, pen, and paper. Sound familiar?

The majority of construction sites and material logistics are run similarly to how Southwest’s system was, with legacy systems that have been around for years, if not decades. Companies keep these systems in place because they work… until they don’t.

For Southwest, the inciting incident was a storm, but what would it be for your company?

Delaying on improving or changing an outdated system “because it still works” is short-sighted and doesn’t leave your company prepared for potential disturbances. And by not upgrading, your company is also missing out on better tools and information to manage the business and support staff.

If you invest in improving the technology that your operations and administrative team rely on daily, it can drastically improve your company’s ability to prepare for the next storm coming your way, which might be...

- Change management of sub-haulers unable to meet your demand, refusing to haul for your company, or going out of business.

- Poor weather conditions slowing or shutting down operations.

- Increased government scrutiny on operations, such as Ontario’s new soil regulations or California’s Bill AB5.

- Dispatchers, admin, or other mission-critical employees leaving your company.

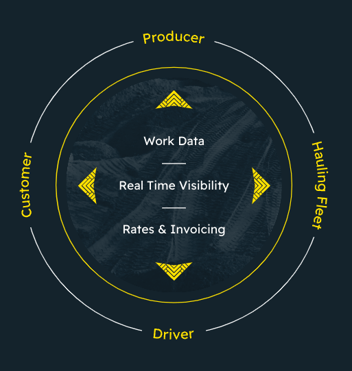

Some of the capabilities of modern platforms like Tread that can help with the issues listed above include the following:

- Maintaining a digital Rolodex of all the haulers, subhaulers, and 3PLs who have ever hauled for you.

- Being able to shift a full day’s dispatch to a different hauling company in a matter of seconds instead of hours.

- Generating a GPS history of when and where your trucks have traveled.

- Real-time archive of digitally stored tickets that can be easily shared with drivers, customers, and DOTs.

- The ability to quickly pivot a full day’s or even a week’s dispatch schedule.

- Solid support and training materials so that new employees and drivers can be onboarded quickly.

Features like the above may not be needed on a daily basis, but when the next disaster strikes, they can save your company from spiraling.

On a day-to-day basis, Tread helps you secure trucks faster, evaluate subcontractors and sites, accelerate your logistics, drive efficiency, and increase profitability. But should something happen, Tread can also be your mission-critical application that prevents your company from becoming the next Southwest.

Schedule some time with our team and find out how Tread can be your mission-critical platform!

Read On

Unveiling Tread Horizon: The Ultimate Construction Materials Intelligence Platform

Pioneering a Comprehensive Platform for the Construction Materials Industry

Tread customer story: Rhino

About Rhino

Vertical: Fleets, Brokers & DriversCompany size: 20 peopleNumber of trucks: 13...

5 Reasons Why You Should Visit Tread at CONEXPO-CON/AGG 2023

CONEXPO-CON/AGG 2023 is almost here! If you’re reading this, you’re just as excited as we are....